While approaching factories, there are two types of production, low and high volume. With each type of product you’re producing there are pros and cons to utilizing these volume methods. Of course, certain types of raw materials or production methods cannot be managed or produced in both methods. Meaning for a rare raw material, they may not produce at high volume. In some cases if an order is too small, the labor and machine change costs may not be advantageous to the producer and they could decline your order. These are just examples of challenges, we’ll now explain low and high production volumes.

Low production orders will include lower order volumes and are at the discretion of your factory to accept or not. You will have to factor in the tooling or mold cost that may, in some cases, offset the per unit cost. With low production, you’re often paying higher for the per-unit cost but are allowed to order less than 100,000 units. Each factory will have their own volume as to what meets “low production” quantities. Some of the advantages of low production orders include less order volumes to commit to, low inventory retention costs, quicker changes, shorter lead times and ability to move more quickly. Some constraints may occur when it comes to frequent shipping costs and time delay to meet your customers’ needs.

A good problem to have is when your demand is high enough that you exceed your low production orders and you have to purchase more products. If this happens, you will have to work with your factory to meet the demand. Some resolutions for this problem may be to increase production runs, order new tools or molds and in the worst case, find an additional or new production partner.

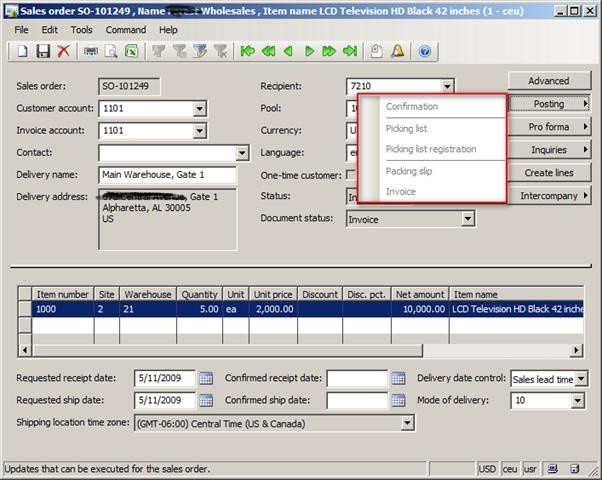

A business may also decide to do high volume production to be able to reduce production costs on a per-unit basis, retain higher inventory levels, reduce shipping costs and meet demand. With high production you’re committing to your manufacturer to buy over a certain number of goods. The factory will also acclimate to meet your requirements to produce most efficiently. Oftentimes this will include automation, priority in production and more support and collaboration with the factory partner. There are, of course, some drawbacks with large production volumes that include less flexibility when it comes to iterations and enhancements. In some cases, the tooling may cost more and the factory may ask for more notice of purchase orders in advance to purchase raw materials.

It is very important to understand how many units you intend to purchase, how much flexibility your business may require and the understanding of the capacity of your manufacturing partner. If you intend to continue to produce low volume parts, it will be in your best interest to partner with a facility with similar production expectations. In the event that you go from a high volume producer to a lower volume producer or vice versa, you will see many challenges around machine capabilities, accommodations by the factory, tooling costs and production prioritization.

This is something you’ll want to work towards, review your data and work with your manufacturer closely to get it right. In the event that your business is not quite sure what the needs are or how to identify them, you may want to speak to a supply chain partner, like Victure Group, to develop a greater understanding for how production on your product or part works. Planning at the beginning of your production and getting insights from experts will help save your company time and money and improve quality.

For product sourcing, you’re suggested to join the following LinkedIn groups

China Sourcing- China Sourcing, Networking, Import, Export, Trading, Manufacturing | Groups | LinkedIn

Green Economy- Sustainable, Circular, Green Economy Forum, Networking, Supply Chain | Groups | LinkedIn

Vietnam Sourcing- Vietnam Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Indian Sourcing- India Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Asia Sourcing- Asia Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Gift and Premiums- Gifts and Premiums | Groups | LinkedIn

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

June 30, 2021

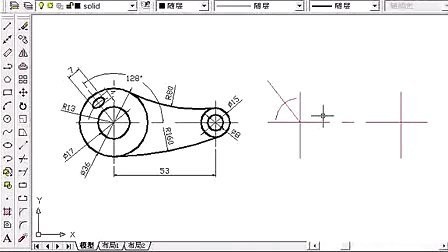

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production

June 03, 2021

Mistakes When Approaching FactoriesLow and High Production