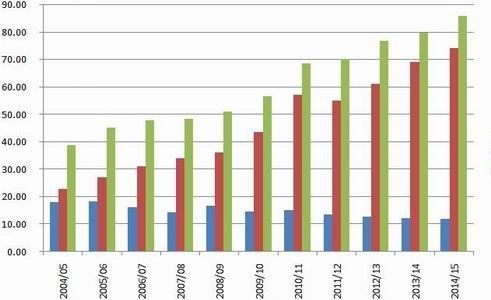

While working on a new product or business, there are many challenges that you will experience. One of the biggest financial challenges will be centered around inventory and production costs. The cost of production, replenishing inventory and managing a warehouse will all affect the cash flow of the business and the chances of success.

Prior to connecting with any factory to produce your goods, a business should look to understand their order volume, sales, production and distribution plan to ensure they’re partnering with a factory that is the correct size for their business needs. Although it may seem easy to contact a manufacturer to make your goods, there are many considerations that go into this process. Additionally, the factory will also be evaluating a partner to determine if your business can grow together and likelihood of success.

These terms to consider as a buyer or importer:

● Production timeline

● Demand planning

● Shipping

● MOQs

● Part and assembly count in production

● Distribution

● Order cycles

When working with a factory, there are many costs that the owner must consider before signing a deal with a potential buyer or importer. These will include understanding the raw material needs, the overhead or labor, the machinery, assembly requirements, future potential for growth, intellectual property constraints and, most importantly, order volumes. The factory is also trying to ensure that they can grow.

Things the factory will be looking to understand:

● Labor requirements

● Raw materials

● Automation capabilities

● Machinery

● Holiday planning

● National closures planning

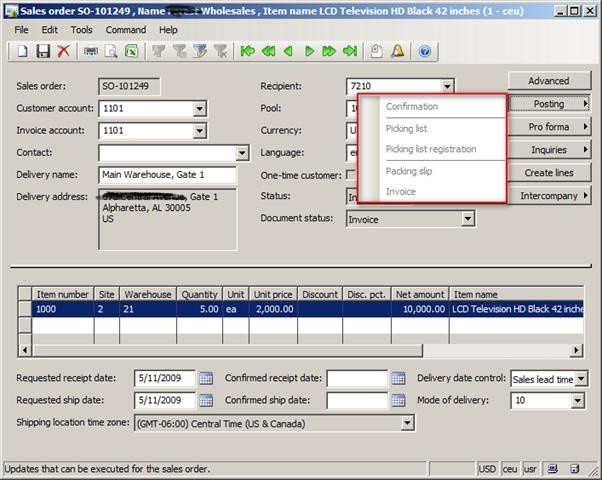

● Software needs (if any)

As a buyer or importer, it is crucial to understand what your expectations are around order receiving, future sales and distribution needs, order volumes and order cycle times. If you understand clearly and share with your factory the expectations for production, you can work towards mitigating risks. Similarly as a buyer, you should be looking to see how a factory will plan to kick-off your production. Through understanding the factory’s needs, you can mitigate certain risks around time, quality and money. Of course, the numbers that are decided on for order volumes, production times and expectations should be continually monitored and revisited to adapt to any changes in the markets. This will help ensure your business is trying to operate as efficiently as possible.

If you’re looking for assistance on developing your supply chain, you may reach out to Victure Group

For supplier sourcing, you’re suggested to join the following LinkedIn groups

China Sourcing- China Sourcing, Networking, Import, Export, Trading, Manufacturing | Groups | LinkedIn

Green Economy- Sustainable, Circular, Green Economy Forum, Networking, Supply Chain | Groups | LinkedIn

Vietnam Sourcing- Vietnam Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Indian Sourcing- India Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Asia Sourcing- Asia Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Gift and Premiums- Gifts and Premiums | Groups | LinkedIn

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

CAD, BOM, DFM & IPLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production

June 03, 2021

Mistakes When Approaching FactoriesLow and High Production