When working with new product companies, we’ve often seen buyers underestimate topics like initial order volumes, distribution plans and factory size when approaching manufacturers.

When working with suppliers, it’s important to have a roadmap, distribution strategy, and sales projections. If you’re working with international suppliers, they will be interested in understanding your value proposition and how your business will align with their goals. In the stages, after you’ve signed an NDA – you should be honest about your order volumes, sales projections and development plans.

If you promise a factory a certain number of orders when your actual order volume is less than a fraction of that, the relationship can become strained. When approaching new factories, you should also be mindful of the size of your organization in relation to the factory. If you approach Foxconn to produce 500 units of your new hardware piece, the effort will likely generate little interest from a company so large. If you do manage to seal a deal with a large manufacturer, but have lower order volumes, you will be faced with the reality that your product is likely low on their priority list. You should search for companies that are interested in working with your organization, agree to the order volumes, have the capacity to complete the orders and show opportunity for growth.

Important to note: An importer/buyer should also be wary or mindful of factories that have an existing relationship with your competitors. If the factory is showing off your competitor’s products while you’re visiting, they will likely do the same with your products.

When working with your factory and a supply chain agent, in addition to being transparent on order volume and roadmap, you should also clarify the distribution plan for your goods. This will allow them to properly plan for certifications and regulations that they may have to meet. Meaning if you’re intending to sell your medical device in the USA, you should ensure the factory is complying with ISO 13485:2016 standard or if you’re launching a hardware piece in the EU, making sure it complies with Conformite Europeenne (CE). Separately, if you’re planning to enter into a big retailer, understanding the testing and packaging protocol will help your business and the factory get ahead in planning for those opportunities.

Aligning with the factory that is the right size can be rewarding. If everything that we’ve discussed seems to line up, then it could be a great opportunity. For more information, support and sourcing, reach out to Victure Group!

China Sourcing- China Sourcing, Networking, Import, Export, Trading, Manufacturing | Groups | LinkedIn

Green Economy- Sustainable, Circular, Green Economy Forum, Networking, Supply Chain | Groups | LinkedIn

Vietnam Sourcing- Vietnam Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Indian Sourcing- India Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Asia Sourcing- Asia Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Gifts and Premiums- Gifts and Premiums | Groups | LinkedIn

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

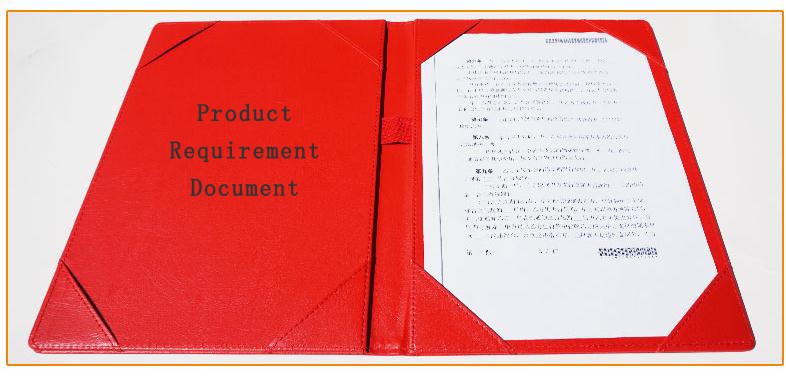

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production