goods will be designated as the “organization.”

What are the differences and which is the best for your company?

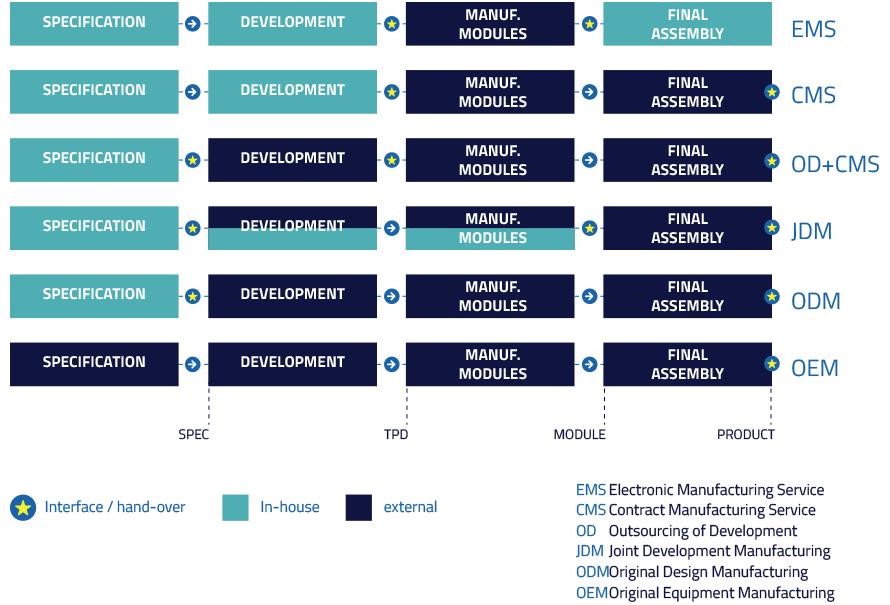

When working with different partners to produce a product, there are many different terms to define the type of factory that you’re working with. You’ve most likely heard of contract manufacturers (CM) or suppliers, but what may sound unfamiliar is OEM, JDM and ODM. When reading this article, the buyer or importer of the goods will be designated as the “organization.”

What are the differences and which is the best for your company?

OEM

OEM is an original equipment manufacturer which is similar to a work-for-hire. The organization is paying the OEM to make all the goods according to the specifications that the buyer provides. The OEM, as a factory, does not own the IP nor the trademarks. Instead, these are owned by the organization The organization also must oversee all the product marketing, sales, financial and distribution responsibilities of the final goods.

This is the most popular of the three because it allows for the organization to oversee and maintain a high level of control for the final goods. The factory will oversee the production, plan for labor and overhead costs, order raw material, utilize machinery, scheduling and choose the systems.

ODM

ODM stands for original design manufacturer where the designing & engineering is handed off to the factory. An organization will connect with factories to take the idea into engineering phases. The ODM will bear the engineering labor and initial creation costs, but they will maintain ownership over the IP. The organization in this case will be able to place their own branding on the goods, but not own the IP. The organization may choose this route to lower standard upfront costs like R&D, engineering, and labor costs. The organization will also be able to access new equipment, and offer new features or materials.

The drawbacks for an organization to choose ODM are around lack of exclusivity, not owning the IP and less flexibility when it comes to MOQs & product costs.

JDM

JDM is a joint development manufacturer and is a little more complex than the two discussed above. JDM includes some original design manufacturing and original equipment manufacturing, but relies heavily on partnership with the organization & factory from start to finish. The factory will provide certain components and designs but the organization is collaborating as partners throughout. An example would be electronics that require specific components or even parts that may need to be off the shelf. It will require frequent communication, passes of phase gates together and teamwork to overcome challenges.

The benefit for the organization to utilize JDM is to be involved in the process of production and closely collaborate with the manufacturer. The organization is not immediately bearing any of the labor costs but may see it factored into the unit cost. More importantly, JDM requires a very close partnership with the factory to deliver on the product goals. The outlines of the relationship should be identified in an MSA and SOW prior to kick-off.

Which one is best for your business?

It all depends on the type of products you’re making, the sourcing nation, the goals of your organization and the level of oversight and/or financial responsibilities required. With each of these, it is important to prioritize complexity, future growth opportunities and the need for IP that align with the organization’s goals. While the output and responsibilities are quite different, one thing that remains the same is the strong need for great manufacturing relationships and vendor management. Establishing a strong symbiotic relationship with suppliers and proper project oversight are keys to success. With this in mind, if you’re looking for assistance on developing your supply chain, please reach out to Victure Group for more information!

For product sourcing, you’re suggested to join the following LinkedIn groups

China Sourcing- China Sourcing, Networking, Import, Export, Trading, Manufacturing | Groups | LinkedIn

Green Economy- Sustainable, Circular, Green Economy Forum, Networking, Supply Chain | Groups | LinkedIn

Vietnam Sourcing- Vietnam Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Indian Sourcing- India Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Asia Sourcing- Asia Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn