As the world begins its transition to electric cars, there are businesses looking to jump into the market as consumers gear up for next steps. Companies that are in the EV race include Ford, GM, Tesla, Kia, BMW, Xiaomi, Rivian, Hyundai, Volkswagen, Arrival, Nikola, Xiopeng Motors, Faraday Future, Lucid Motors, Nio, WM Motors, OIa, Zenobe, StoreDot, Rimac, Gunsel, Sono, Enel Ex, Electreon, LightYear, and more.

These vehicles include consumer models, public transit buses, subscription memberships, autonomous ride-shares, and trucking from companies around the world. All will require new technologies and infrastructure to ensure the success of their products.

These new technologies will require cooperation and ecosystem developments from their respective governments and heavy reliance on specifically produced components. While there is the intent to reduce carbon footprint by transitioning away from traditional fuel, the hope is that these car manufacturers will take similar thoughtful considerations when sourcing.

Some of the challenges that manufacturers of electric vehicles will face include sourcing of raw materials as the world emerges from economic challenges from the pandemic, complying with government policies, building out charging networks, sourcing semiconductors during increasing supply shortages, designing the vehicles for safety and material choice to name just a few.

In the EV industry, some businesses are becoming creative in how they’re manufacturing, sourcing parts, and approaching raw materials. The company, Arrival, which is working with UPS to develop delivery vehicles, is utilizing plastics instead of traditional steel or aluminum for parts and doing micro-plant assembly in local markets. Similarly, companies are working to manufacture their own batteries and similar components.

They’re also working on new raw materials to meet some of the challenges of EV that include silent motors, charging networks and weight. Since EV batteries account for around 43% the weight of a car, while traditional engines are only 25%, companies must engineer ways to balance weight while maximizing performance. However, consumer safety must not be compromised as companies look to solve design challenges.

There have also been a number of shortages around semiconductors requiring all these companies to act fast to meet the production goals set forth by executives, investors and governments. Companies are looking to offer different value propositions to attract new potential customers while also attracting existing transit consumers to buy in.

In contrast to traditional production of vehicles, EV require unique components and parts with production methods that haven’t been made at scale yet. Larger public manufacturers in the United States have taken it upon themselves to invest in new battery design. Although European nations and the USA are looking to invest into the battery plants, there are constraints around raw materials for these parts. Traditional manufacturers of these parts like China, Japan and South Korea have already established supply chains for EV batteries. (Among many reasons, the nickel refinement process is more expensive stateside and Lithium is processed at scale in Asia.)

Amidst the pandemic, we’ve also seen changes in consumer spending, the need for a diversified supply chain, the importance of contingency planning and global dependency for goods & services.

The biggest challenges that we will likely see around the implementation and official transition to EV are fiscal constraints due to the heavy capital investments of manufacturing new vehicles, the constraints from component sourcing and quality control. Contact Victure Group for more information on supply chain oversight for EV industries & more

For product sourcing, you’re suggested to join the following LinkedIn groups

China Sourcing- China Sourcing, Networking, Import, Export, Trading, Manufacturing | Groups | LinkedIn

Vietnam Sourcing- Vietnam Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Indian Sourcing- India Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

Asia Sourcing- Asia Sourcing, Networking, Import, Export, Trading, Manufacturing, Supply Chain | Groups | LinkedIn

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

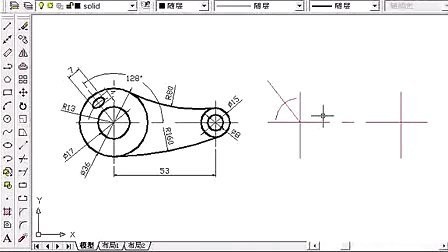

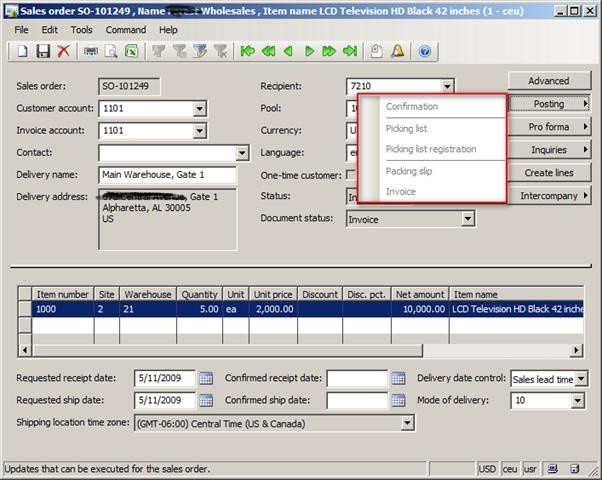

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production