From my observation, the IPO (International Purchasing Office) center has been changing to other major cities of China from Hong Kong over the past decades. You’re no doubt outdated if you’re still looking for sourcing partner from Hong Kong.

Over a decade ago, I visited HK a lot when I started working in the international business, because most IPO’s were located in HK as a city with a lot of comparative advantages in language, culture, logistics, etc. But this city is losing its appeal to international buyers in most recent years.

Since the early 1980s, China has started to open to the whole world. More and more people in big mainland China cities such as Shenzhen, Guangzhou and Shanghai can speak very good English and other foreign languages, this makes international communication much easier than before. People from the country have more and more communication with the external world, they’re getting much better on the understanding of foreign culture.

The logistic in mainland is rather mature nowadays. Shenzhen is already the world No.1 container loading port, while Shanghai has become the world biggest port in terms of cargo output. High speed railways and freeways reach most of the cities across the country. With more production facilities moving to other cities of China, HK will definitely lose more advantages in logistics.

One day I brought the same topic to an American guy why still using sourcing service from HK, he said local HK people are more “international and smart”, I told him, “you have to pay HK$40000 per month for a SMART HK guy, while I can make a whole team here in Shenzhen with the same amount of money”!

China is a big country, with the trend of supply chain being move to other inland cities and provinces, international buyers have to go further for product sourcing, factory visit, etc. At this point, HK people have even less advantages—they’re somehow regarded as “foreigners” for most people who live in mainland China. Even within the same country, different places have totally different culture, it’s hard for them to handle all the situations.

On the other hand, a lot of local mainland people are very professional in certain product and technology areas. Many of them have been working in their own areas for dozens of years, this makes them very powerful when competing with HK people.

The truth is, many IPO’s including Best Buy, Carrefour, Metro have been moving their purchasing office to the mainland. Are you still looking for your sourcing partners in HK? Time to change now!

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

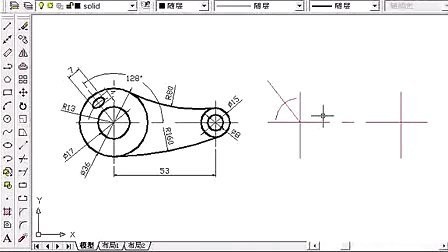

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production