The Chinese word for “crisis” 危机 is often seen as the individual characters for “danger” and “opportunity”. The novel coronavirus has certainly become a crisis for us as International Buyers.

The danger that we are experiencing is wide ranging from: China visit cancellations, shipment delays, customer orders cancelled, our businesses completely closed, loss of millions of dollars in earnings, and even the fear of our employees being exposed to the virus. These dangers are real and ever present – and likely to grow in the coming weeks and months. The danger can take a large toll on us personally and professionally.

Our challenge as Supply Chain Mangers is to find, foster, and nurture the opportunity which this crisis presents. We must move from a reactive position to a proactive position. We must show leadership for our businesses – and overcome the dangers which confronted us. We have the opportunity to connect even closer with our supply chain partners, to seek out alternate sourcing countries & options, and to develop creative methods for acquiring the goods and services needed.

Best practices for seizing the opportunity is to: 1) expect delays – and be able to communicate them throughout your organization, 2) assess inventories and orders – what materials and orders to prioritize or ration, 3) establish flexibility in your planning – schedule additional lead time, ship smaller volumes more frequently, temporarily lower minimum stock levels, and 4) stay informed of the ever changing situation.

One of the most successful best practices for managing a crisis through opportunity is to work with an experienced, reliable, and trusted sourcing partner based in China. We at Victure Industrial have a very skilled and trained team located throughout China to support your supply chain management needs. We are prepared to provide you complete assistance with the crisis. Our team is ready to work with you to deal with the danger. And we are ready to work with you to proactively seize the opportunity to overcome the crisis. Please let us know how to serve you.

To make up your cancelled travel plans and trade fairs of your China Sourcing activities, it’s important to access Chinese suppliers online, you can use some tools such as LinkedIn which covers 400 million professionals globally. Here are some LinkedIn groups to recommend for China Sourcing-

China Sourcing, Import, Export- https://www.linkedin.com/groups/4462099/

Phone Accessories- https://www.linkedin.com/groups/4420760/

Wearables- https://www.linkedin.com/groups/6798191/

Gifts and Premiums- https://www.linkedin.com/groups/4421652/

Bluetooth- https://www.linkedin.com/groups/4692512/

IFA- https://www.linkedin.com/groups/4796982/

Wechat- https://www.linkedin.com/groups/5123967/

Shenzhen Business Networking- https://www.linkedin.com/groups/5063375/

Asia Sourcing- https://www.linkedin.com/groups/8909383/

If you need any assistance on your Chinese supply chain, visit www.victuregroup.com

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

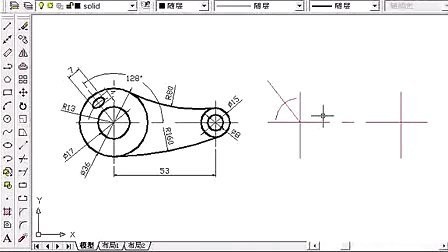

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production