Due to the pandemic, supply chains around the world have been impacted by an unprecedented number of factors that include labor restrictions, national lock downs, factory closures, raw material shortages and changes in consumer buying trends. While the world starts to open back up, businesses will continue to feel the effects of the pandemic due to container shortages which in turn impact transportation prices and the accessibility to finished goods.

Although goods are shipping, there has been a bottleneck of containers waiting at ports to unload onto trucks and also preparing empty containers to return back to their origin countries. The containers are held up at inland depots, cargo ports and on vessels. One of the ports experiencing ongoing unloading and bottleneck challenges is the port in Los Angeles. To plan around this, freight providers are trying to find other ports, routes or utilize other modes of transportation once the goods land in the USA.

Who owns the shipping containers? Shipping containers are owned by shipper lines, leasing companies and sometimes by the shippers themselves. Shipper lines, like Maersk, will own their own containers to help facilitate the transfer of goods. However, this can be costly to maintain, repair, store and reposition. Containers are also owned by leasing companies that rent out the containers to shipper companies. An example of a leasing company is Triton. Triton is able to manage demand, locations and rent out to shipper lines for use. In some cases smaller shipper companies will own their own containers.

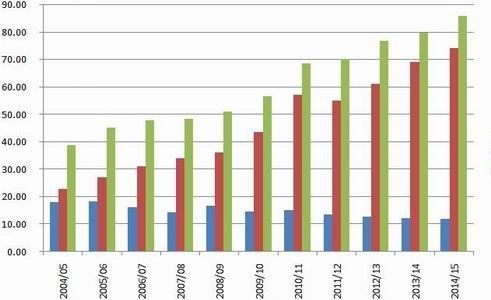

Why can’t more containers be made? Well, they are! They’re working fast to build new containers in China. It is estimated that container rentals have gone up about 50%. New containers are at a cost of $2,500 while previously being $1,600 at the same time last year.

It is estimated that for every one hundred containers sent to North America from China, only around forty have been returned. While China and parts of Asia have been open for months, other supply chains are working hard to return to normal, but are still feeling the ripple effects of the pandemic. In areas outside of China, there have been ongoing shipment delays and price fluctuations that have caused some suppliers to have to increase costs or in the worst case scenario, go out of business. Containers from Europe have also been experiencing delays in return and there are shortages.

What will happen next? Although official lockdowns in North America happened almost a year ago, we are still feeling the effects and are expected to continue to experience higher costs and longer lead times. In China, the government and suppliers are working to facilitate new container creation while closely monitoring supply chains. Logistics companies around the world are also trying to develop more efficiencies in their unloading processes, invest in new systems and reduce free time or detention periods. While 2021 still seems volatile and unexpected for container availability, global manufacturing and logistics providers are hoping 2022 will trend more normal.

For more help on demand planning and supply chain advice and navigating these challenging times, contact Victure Group for more information!

Join the following groups for your sourcing needs-

China Sourcing- https://www.linkedin.com/groups/4462099/

India Sourcing- https://www.linkedin.com/groups/8454669/

Vietnam Sourcing- https://www.linkedin.com/groups/8815822/

Asia Sourcing- https://www.linkedin.com/groups/8909383/

Gifts and Premiums- https://www.linkedin.com/groups/4421652/

Circular Economy- https://www.linkedin.com/groups/13908783/

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production