What is a quality inspection report? A quality inspection report is the checking and monitoring of the product (while in various stages of production) to review the quality in comparison with the preset conditions and requirements.

Who does the quality inspecting do? Depending on the relationship with your vendor, you can often visit the facility during production to review the quality of your products. Sometimes a factory may also offer to do a quality check utilizing their in-house or their preferred quality controllers. While these seem like cost and time saving opportunities, you should go with a third party quality inspector like Victure to thoroughly and accurately review the quality of your goods.

Pricing? An inspector will usually provide a daily rate that may or may not include transportation and food and or accommodations. The inspection can range from one day to a few days, depending on the size of the order, assembly methods and facility location.

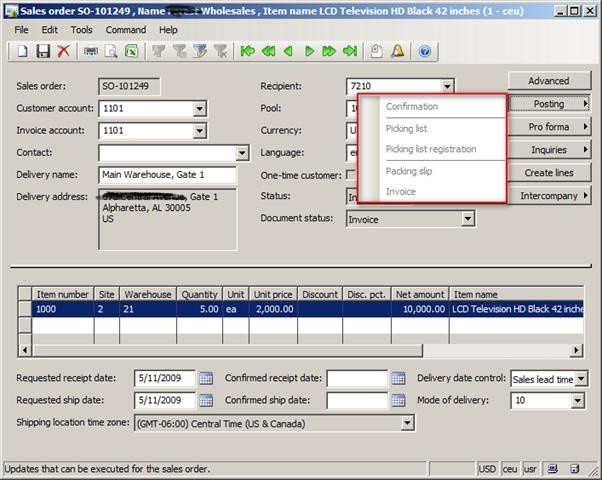

Preparing for a quality inspection? When preparing for an inspection, your quality management company will check in with you to understand the aspects of the products that you want to review. They will oftentimes set up a pre-designed criteria checklist. You will also be able to add photos or provide the inspector with a sample of the product. However, if you’re working with China, your factory should have your signed-off version of a golden sample for the inspector to match. Prior to the visit, the tolerance or range of acceptance should be drafted between the buyer (you) and your inspector.

When reviewing the product during inspection, the factory and your inspector will segregate a group of that product to closely review. They will do everything from performance testing, cosmetic review and dimensional checks.

How is the inspection report graded? The inspection will have a pass or fail grade based on the qualitative and quantitative requirements set forth in the range of acceptance. The defects are categorized as “Minor, Major, Critical” and there will be a certain number of each that are accepted.

What else is included in the report? The inspector will also include photos of your products, the factory exterior, the pallets (if loaded), the calibration date of the machines that are being utilized and performance testing results. This can also include descriptions of the facilities, the safety considerations, the interactions with workers and sometimes video. When more information is provided by the factory and the inspector, this will increase your chances of a better outcome.

In the event that your product does fail, you would work with the inspector (if you have them as a partner) for next steps. In the event that you use a third party for one time inspection, it will be up to you to negotiate a rework or credit for any errors. In this case, utilizing a long term agent partner, like Victure, will help review the quality of your products and help liaison with your factory when defects occur.

Join the following groups for your sourcing needs-

China Sourcing- https://www.linkedin.com/groups/4462099/

India Sourcing- https://www.linkedin.com/groups/8454669/

Vietnam Sourcing- https://www.linkedin.com/groups/8815822/

Asia Sourcing- https://www.linkedin.com/groups/8909383/

Gifts and Premiums- https://www.linkedin.com/groups/4421652/

Circular Economy- https://www.linkedin.com/groups/13908783/

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

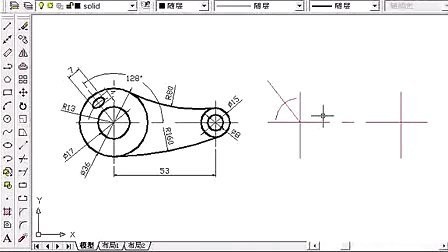

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

Product Requirement DocumentLow and High Production