Let’s start this discussion with some definition of terms according to the American Society for Quality (“ASQ”):

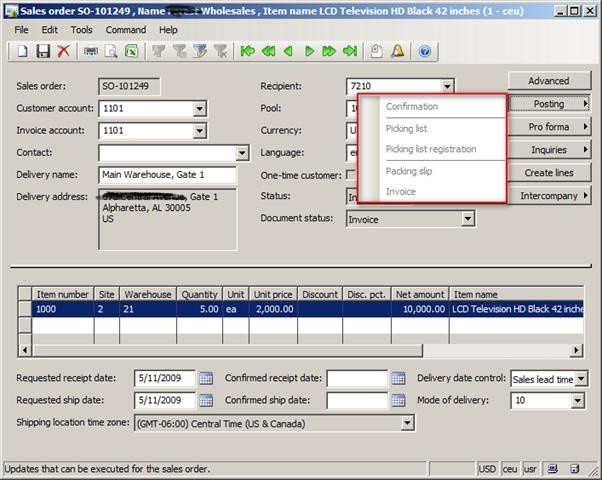

“Inspection”: A verification activity. For example, measuring, examining, testing and gauging one or more characteristics of a product or service and comparing the results with specified requirements to determine whether conformity is achieved for each characteristic.

“Quality”: a subjective term for which each person or sector has its own definition. In technical usage, quality can have two meanings: 1) the characteristics of a product or service that bear on its ability to satisfy stated or implied needs; 2) a product or service free of deficiencies.According to Joseph Juran, quality means “fitness for use”; according to Philip Crosby, it means “conformance to requirements.”(1)

Inspections can occur at multiple points within a manufacturing operation (e.g. at incoming raw materials / parts receipt, at various points during the manufacturing process, and prior to shipment of finished products).

While many factors impact the success, or failure, of a business that sells products, there is no doubt that the business will not be able to achieve and then sustain success if it does not continuously provide products that meet the Quality requirements / expectations of its customers.

Now, let’s review some quotes that you may have heard before:

“No matter how much you evaluate the quality of a product that has been already manufactured, this will never lead to manufacturing products of good quality.” Taiichi Ohno

“Inspection does not improve the quality, nor guarantee quality. Inspection is too late. The quality, good or bad, is already in the product. As Harold F. Dodge said, ‘You cannot inspect quality into a product.’” W. Edwards Deming

Let’s also acknowledge that: (1) there is a “Cost of Quality” for every organization which can be further broken down into the “Cost of Good Quality” and the “Cost of Poor Quality”; and (2) the Cost of Poor Quality far outweighs the Cost of Good Quality.(2)

“The biggest cost of poor quality is when your customer buys it [a competing product] from someone else because they didn’t like yours”. W. Edwards Deming

Further, let’s also re-visit a couple of points I made in a prior article that I posted on LinkedIn on 28 Jan 2021 titled “The Poor Quality ‘Myth’ regarding China-based Suppliers”:

“In China, as in most other places, “you get what you ask for”. Therefore, you need to be very careful when you specify your requirements to your suppliers – particularly those with whom you have not previously done business. Do not assume that any of your requirements – especially those regarding quality controls – are already known / understood, so you won’t need to explicitly state them in your RFx documents.”

“It is very important to note that as part of your diligence, you really should make in-person visits to your potential suppliers in China – using either your own company’s personnel or those of a trusted agent.”

Finally, I am going to assume for purposes of this discussion that you, the reader, care about establishing a long term business relationship with your customers and that you desire to grow your sales revenue while also meeting profitability objectives.

So… given all of the above, what is the point I am trying to make?

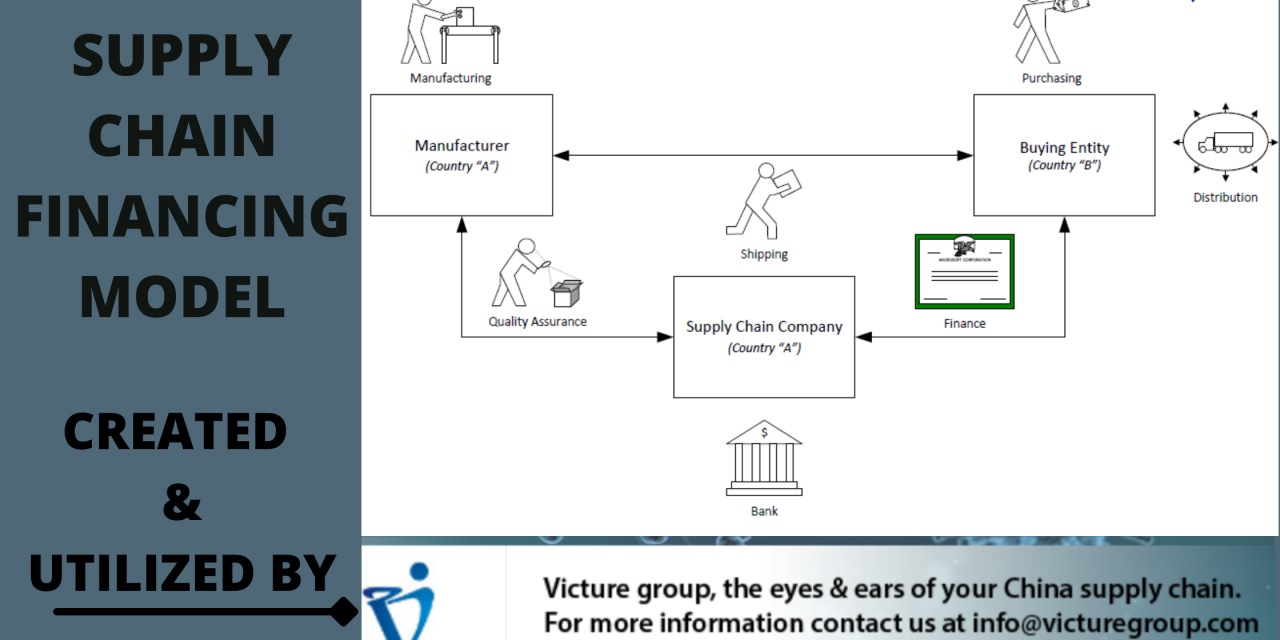

The point is that, regardless of where in the world your suppliers are located, you need to be prepared to spend the time and the money to fully evaluate the facilities, equipment, and Quality Management System (“QMS”) that will be used by your potential suppliers to ensure that they can consistently / reliably provide products that meet your Quality requirements / expectations. The most important evaluation to conduct is that of the QMS.

There are many things to consider when conducting an “audit” of a potential supplier’s QMS. I am not going to get into those details here. However, if you do not have the appropriate resources within your own company to conduct proper QMS audits, you must absolutely identify and engage with an external entity who can perform those audits on your behalf and provide you with a complete, honest, and direct assessment of the potential supplier’s QMS.

If a potential supplier has great facilities and great equipment, but a “weak” QMS, you should think very carefully about doing business with them – especially if they are making products that will have your company’s name on them.

You also need to be willing to spend the time and the money for on-going “surveillance” of your suppliers – including, as appropriate, for outbound inspection of Finished Goods before they are shipped to you. This is especially true where the suppliers will be producing products made to your specifications.

However, while you may choose to implement outbound inspection of Finished Goods, this process will be most useful for ensuring that nothing has gone out of control within the QMS. If results from the inspection detect problems in the QMS, then those results can be used to “raise the red flag” and to drive a corrective action response from the supplier.

The important point – as previously noted – is that you cannot rely solely on the use of outbound Finished Goods Inspections (or any other types of inspections) as a means of ensuring that products of appropriate quality are being shipped to you.

Benjamin Franklin once famously said that “An ounce of prevention is worth a pound of cure.” Translated into this discussion, the upfront investment of time and money that you make to audit and validate the QMS of your potential suppliers will be far smaller than the expenses and other damages you will incur to mitigate the effects of poor quality products being shipped to your customers. Therefore, there is no good reason to not conduct a QMS audit prior to moving forward with any new supplier.

For assistance on your quality inspection or quality system management, visit our website at http://www.victuregroup.com/

Join the following LinkedIn groups for your Asia Sourcing activities

China Sourcing- https://www.linkedin.com/groups/4462099/

India Sourcing- https://www.linkedin.com/groups/8454669/

Vietnam Sourcing- https://www.linkedin.com/groups/8815822/

Asia Sourcing- https://www.linkedin.com/groups/8909383/

Gifts and Premiums- https://www.linkedin.com/groups/4421652/

Circular Economy- https://www.linkedin.com/groups/13908783/

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production

June 30, 2021

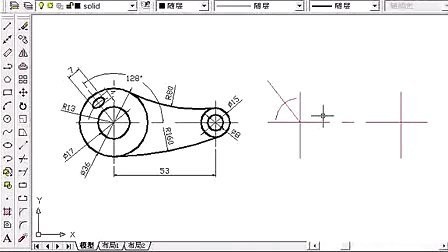

CAD, BOM, DFM & IPLow and High Production

June 17, 2021

Order Volume ConsiderationsLow and High Production

June 09, 2021

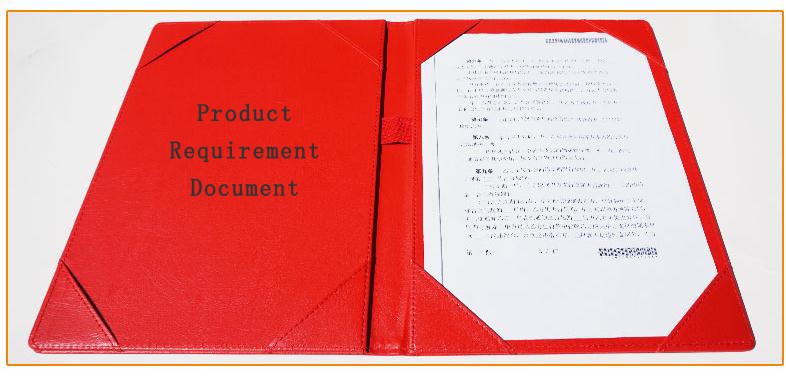

Product Requirement DocumentLow and High Production