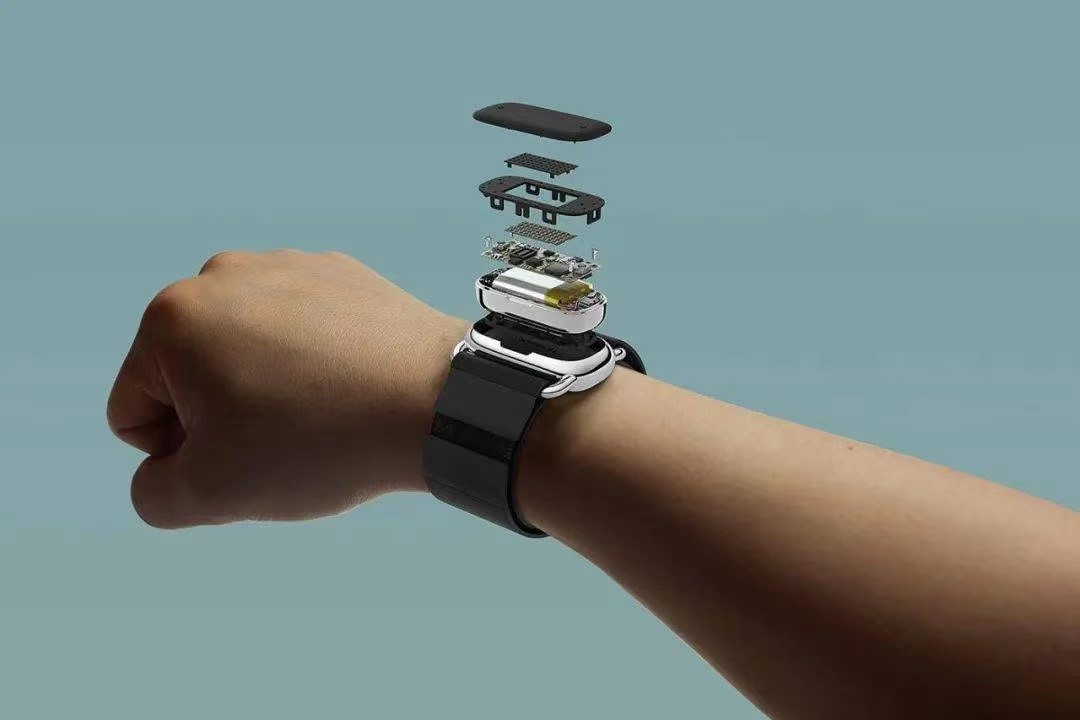

What is pre-production sample?

Pre-production sample is provided before mass production. It’s an important tool of communication between the seller and the buyer. Sometimes it’s called the “Golden Sample” and helps both the seller and buyer be on the same page in terms of cosmetics, functionalities, reliabilities, labelling and marketing during the mass production. The pre-production sample should be identical to the sample you ultimately receive.

A key reason why it’s so important to request a 100% compliant pre-production sample is because of the cultural barriers between the buyer and seller. International buyers could easily get a “yes or ok” answer from supplier. Due to the cultural differences Asian people understand “yes or no” to mean something entirely different from the buyers meaning. Do they really understand you or do they only hear what are you saying? This lack of communication can result in an inaccurate sample. Therefore, the buyer must explain in detail what the sample needs to get the correct product. Culturally a “yes or ok” must be defined to insure a compliant sample product.

What should a pre-production sample come with?

The pre-production sample should come with a datasheet of the sample that describe the main technical specifications and quality requirements. If possible, the pre-production sample shall be submitted for compliance lab testing either to FCC, UL, or FDA, RoHS, etc.

The benefits of pre-production sample

The pre-production sample is a tool of communication between the buyer and the supplier. The buyer must not let the seller take for granted where the buyer manufactures the product. The seller should be more interested in the quality of the product instead of where it came from. The sample should be of nice quality. Sellers don’t really need to know who you are. The quality of the sample is premium.

The pre-production sample gives a chance for both the seller and buyer to make specific changes, if needed, before production. This will help avoid any huge potential risks before mass production.

Often times, in the past the sellers claim they couldn’t provide the 100% compliant pre-production samples to their buyers. This may be because their sales department or the person in charge is not professional or aggressive enough to understand how important the pre-production sample is. How organized or professional is the seller/manufacturer? This must be analyzed.

In reality, many buyers request the first sample and start to place purchasing orders. There are huge potential risks behind this. If the seller is a medium or small company the sales people probably don’t understand what exactly a pre-production sample means.

When should a pre-production sample happen?

Buyers should insist to receive such a pre-production sample before placing the order.

Who should have the pre-production sample?

The buyer, the onsite buyer representative or QC staff, the seller and the manufacture should all have the pre-production samples to make sure all stakeholders are on the same page.

What to do when a supplier doesn’t agree to provide a 100% compliant pre-production sample.

1) In many cases, the sales person in charge is not strong enough to push for it.

2) If it’s due to the lack of process control, it’s a sign that you should consider to turn to a more organized supplier.

3) In some special cases color deviation can be a problem. There used to be a color deviation between the digitally printed proof vs the mass production printing proof. Therefore, the same pantone books or color swatches in the hands of both sellers and buyers can easily solve the problem. Ideally the buyer could have a representative on the ground who can represent its own interest of business. That’s what we do at Victure Inc.

Another situation is when a new product is introduced into production, the seller could provide fragmented information on continuously improved samples. As a buyer, it’s so important to not give concessions on this.

It’s critical that the manufacturer gives a clear explanation of the reason and a solution to proceed.

If you have any questions or need help with your China/Asia sourcing, please visit our website at www.victuregroup.com or message me, Paul Weedman.

Other useful groups about Asia Sourcing-

China Sourcing- https://www.linkedin.com/groups/4462099/

India Sourcing- https://www.linkedin.com/groups/8454669/

Vietnam Sourcing- https://www.linkedin.com/groups/8815822/

Asia Sourcing- https://www.linkedin.com/groups/8909383/

Gifts and Premiums- https://www.linkedin.com/groups/4421652/

Circular Economy- https://www.linkedin.com/groups/13908783/

October 19, 2023

Industrial Clusters in ChinaLow and High Production

October 16, 2023

Most Vital Sourcing Process- Supplier AuditLow and High Production

October 16, 2023

DFM, DFT & DFA for ManufacturingLow and High Production

October 13, 2023

Ultimate Guide for Canton Fair TourLow and High Production

July 08, 2021

Low and High ProductionLow and High Production